Txoj kev txo cov hlau poob hauv engineering tsim

Txoj hauv kev tseem ceeb tshaj plaws yog kom paub qhov laj thawj ntawm kev siv hlau loj, txawm tias qhov sib nqus sib nqus yog qhov siab lossis qhov zaus yog qhov loj lossis qhov saturation hauv zos loj heev thiab lwm yam.Tau kawg, raws li txoj kev ib txwm muaj, ntawm ib sab, nws yog ib qho tsim nyog yuav tsum kwv yees qhov tseeb ntau npaum li qhov ua tau los ntawm simulation sab, thiab ntawm qhov tod tes, cov txheej txheem kev sib koom tes thev naus laus zis txo qhov kev siv hlau ntxiv.Raws li txoj hauv kev uas feem ntau yog nce kev siv cov ntawv zoo silicon steel, rau qhov sib txawv daim ntawv thov scenarios muaj kev faib khoom zoo dua.

1.Optimized sib nqus Circuit Court

Optimizing lub magnetic Circuit Court, tshwj xeeb optimizing lub sinusoidal zog ntawm magnetic teb.Qhov no yog ib qho tseem ceeb heev, tsis yog rau kev ruaj khov zaus induction motors ua.Qhov sib txawv zaus induction lub cev muaj zog synchronous lub cev muaj zog yog qhov tseem ceeb.Kuv ib zaug ua ob lub cev muaj zog nrog kev ua tau zoo sib txawv txhawm rau txo cov nqi hauv kev lag luam textile machinery, ntawm chav kawm, qhov tseem ceeb tshaj plaws yog tsis muaj inclined ncej, ua rau lub sinusoidal inconsistency ntawm huab cua sib nqus magnetic teb.Vim hais tias kev ua haujlwm yog nyob rau hauv high-ceev tej yam kev mob, cov hlau noj nyiaj rau ib tug kuj loj, yog li qhov poob ntawm ob motors yog heev loj, thiab thaum kawg, tom qab ib co kab rov qab xam, vim hais tias cov hlau noj ntawm lub cev muaj zog nyob rau hauv kev tswj. algorithm yog ntau tshaj 2 zaug.Nws kuj tseem ceeb rau koj tias thaum koj ua qhov zaus hloov pauv ceev tswj lub cev muaj zog, koj yuav tsum sib txuas tswj algorithm ua nws.

2. Txo qhov sib nqus ntom ntom

Txoj hauv kev tseem ceeb tshaj plaws yog kom paub qhov laj thawj ntawm kev siv hlau loj, txawm tias qhov sib nqus sib nqus yog qhov siab lossis qhov zaus yog qhov loj lossis qhov saturation hauv zos loj heev thiab lwm yam.Tau kawg, raws li txoj kev ib txwm muaj, ntawm ib sab, nws yog ib qho tsim nyog yuav tsum kwv yees qhov tseeb ntau npaum li qhov ua tau los ntawm simulation sab, thiab ntawm qhov tod tes, cov txheej txheem kev sib koom tes thev naus laus zis txo qhov kev siv hlau ntxiv.Raws li txoj hauv kev uas feem ntau yog nce kev siv cov ntawv zoo silicon steel, rau qhov sib txawv daim ntawv thov scenarios muaj kev faib khoom zoo dua.

3.Optimized sib nqus Circuit Court

Optimizing lub magnetic Circuit Court, tshwj xeeb optimizing lub sinusoidal zog ntawm magnetic teb.Qhov no yog ib qho tseem ceeb heev, tsis yog rau kev ruaj khov zaus induction motors ua.Qhov sib txawv zaus induction lub cev muaj zog synchronous lub cev muaj zog yog qhov tseem ceeb.Kuv ib zaug ua ob lub cev muaj zog nrog kev ua tau zoo sib txawv txhawm rau txo cov nqi hauv kev lag luam textile machinery, ntawm chav kawm, qhov tseem ceeb tshaj plaws yog tsis muaj inclined ncej, ua rau lub sinusoidal inconsistency ntawm huab cua sib nqus magnetic teb.Vim hais tias kev ua haujlwm yog nyob rau hauv high-ceev tej yam kev mob, cov hlau noj nyiaj rau ib tug kuj loj, yog li qhov poob ntawm ob motors yog heev loj, thiab thaum kawg, tom qab ib co kab rov qab xam, vim hais tias cov hlau noj ntawm lub cev muaj zog nyob rau hauv kev tswj. algorithm yog ntau tshaj 2 zaug.Nws kuj tseem ceeb rau koj tias thaum koj ua qhov zaus hloov pauv ceev tswj lub cev muaj zog, koj yuav tsum sib txuas tswj algorithm ua nws.

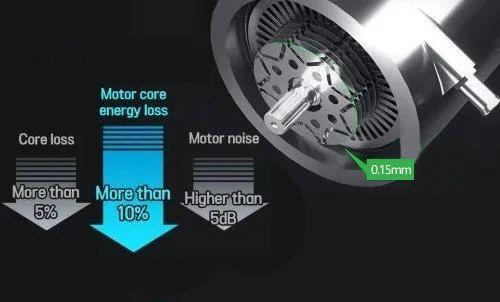

4.Txo qhov sib nqus ntom ntom

Ua kom qhov ntev ntawm cov tub ntxhais hlau los yog ua kom qhov sib nqus conductivity ntawm qhov sib nqus hluav taws xob kom txo tau qhov sib nqus flux ceev, tab sis tus nqi ntawm cov hlau siv los ntawm lub cev muaj zog yuav nce ntxiv;

5.Txo lub thickness ntawm cov hlau nti kom txo tau qhov poob ntawm induced tam sim no

Yog tias cov ntawv txias-dov silicon steel ntawv siv los hloov cov ntawv kub-kuav los tiag silicon steel ntawv, lub thickness ntawm silicon steel ntawv yuav raug txo, tab sis nyias hlau core daim ntawv yuav ua rau cov hlau chips thiab cov nqi tsim khoom. lub cev muaj zog.

6.Qhov txias-dov silicon steel ntawv nrog zoo sib nqus permeability yog siv los txo hysteresis poob.

7.High kev ua tau zoo hlau nti rwb thaiv tsev txheej

8.Kev kho cua sov thiab kev tsim khoom siv tshuab

9.Qhov kev ntxhov siab tom qab cov hlau nti machining yuav cuam tshuam rau qhov poob ntawm lub cev muaj zog, thiab cov kev taw qhia txiav thiab xuas nrig ntaus shear kev nyuaj siab muaj kev cuam tshuam zoo rau kev poob ntawm cov tub ntxhais hlau thaum lub sij hawm silicon steel ntawv machining.Txiav raws cov kev taw qhia dov ntawm silicon steel ntawv thiab kev kho cua sov ntawm silicon steel xuas nrig ntaus ntawv tuaj yeem txo qhov poob ntawm 10% mus rau 20%.

Post lub sij hawm: Nov-27-2023